Classification And Significance Of Defects

Defects may be classified depending on their shape:

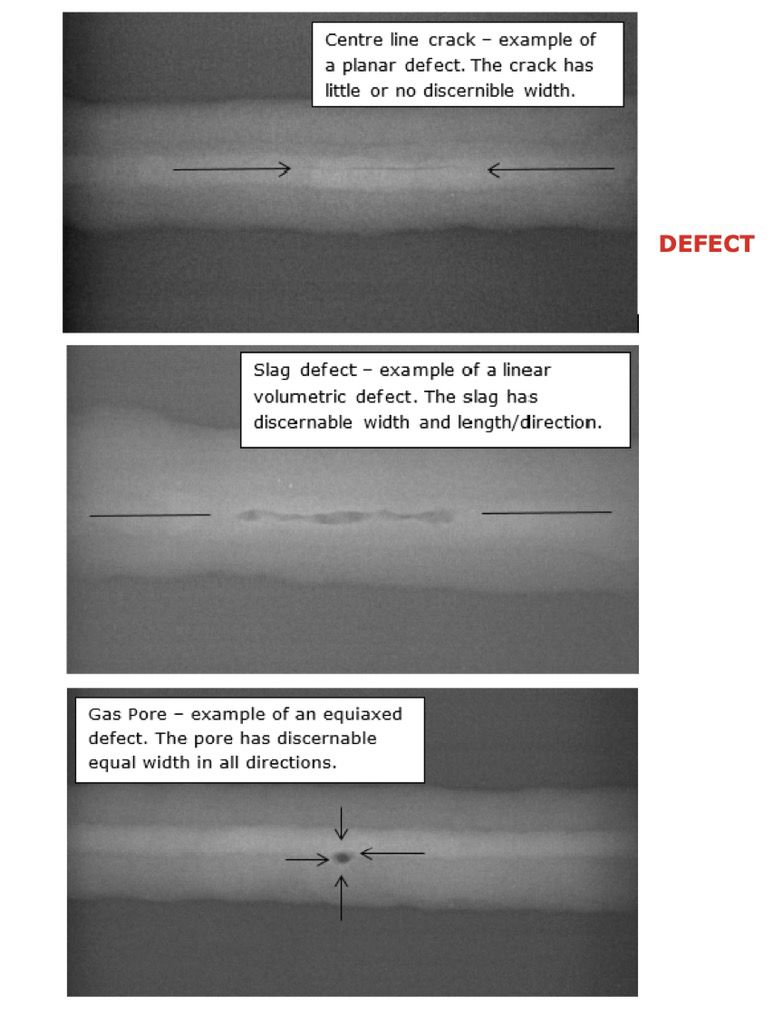

- Planar defects: linear from at least one dimension; crack like, e.g. cracks, lack of fusion. Relative to other defects, these defects usually have a high significance.

- Linear volumetric defects: e.g. slag lines, elongated porosity.

- Equiaxed defects: rounded and non-linear, e.g. gas pores, slag inclusions. Relative to other defects, these defects usually have a low significance.

NOTE

significance is relevant to all manufactured components.

The position of a defect in the cross-section of a weld is also an important consideration. Stress is more concentrated at a surface and corrosion may also be taking place in the region, therefore a non- planar defect breaking the surface may be classed as highly significant defect. In general defects can be classified in severity order as:

Surface linear–Surface rounded–Subsurface linear–Subsurface rounded

The actual defect acceptance or rejection will depend on the defect acceptance levels listed in the relevant specification.